In the contemporary landscape of industrial equipment, the call for sustainability has become increasingly pronounced. Amidst this global shift toward eco-friendly practices, microchannel heat exchangers have emerged as champions of efficiency, offering a sustainable solution for industrial thermal management. This article explores the environmental benefits and sustainability features that make microchannel heat exchangers key players in promoting eco-friendly industrial practices https://www.kaltra.com/microchannel-heat-exchangers.

Microchannel Heat Exchangers: An Eco-Friendly Innovation

Microchannel heat exchangers are at the forefront of sustainable industrial practices, fundamentally reshaping the way industries approach thermal management. The key to their eco-friendly profile lies in several features that collectively contribute to reducing environmental impact and fostering a more sustainable industrial future.

Reduced Refrigerant Charge for Lower Environmental Impact

One of the significant contributors to the sustainability of microchannel heat exchangers is their ability to operate with a reduced refrigerant charge. Traditional heat exchangers often require a substantial amount of refrigerant, leading to potential environmental hazards. Microchannel designs, on the other hand, minimize the use of refrigerants, aligning with global efforts to reduce greenhouse gas emissions and promote environmentally responsible industrial practices.

Energy Efficiency and Carbon Footprint Reduction

Microchannel heat exchangers excel in energy efficiency, a critical aspect of sustainability in industrial operations. By optimizing heat transfer processes, these exchangers contribute to lower energy consumption, ultimately reducing the carbon footprint of industrial facilities. The enhanced efficiency translates into tangible benefits for both the environment and the operational costs of industrial processes.

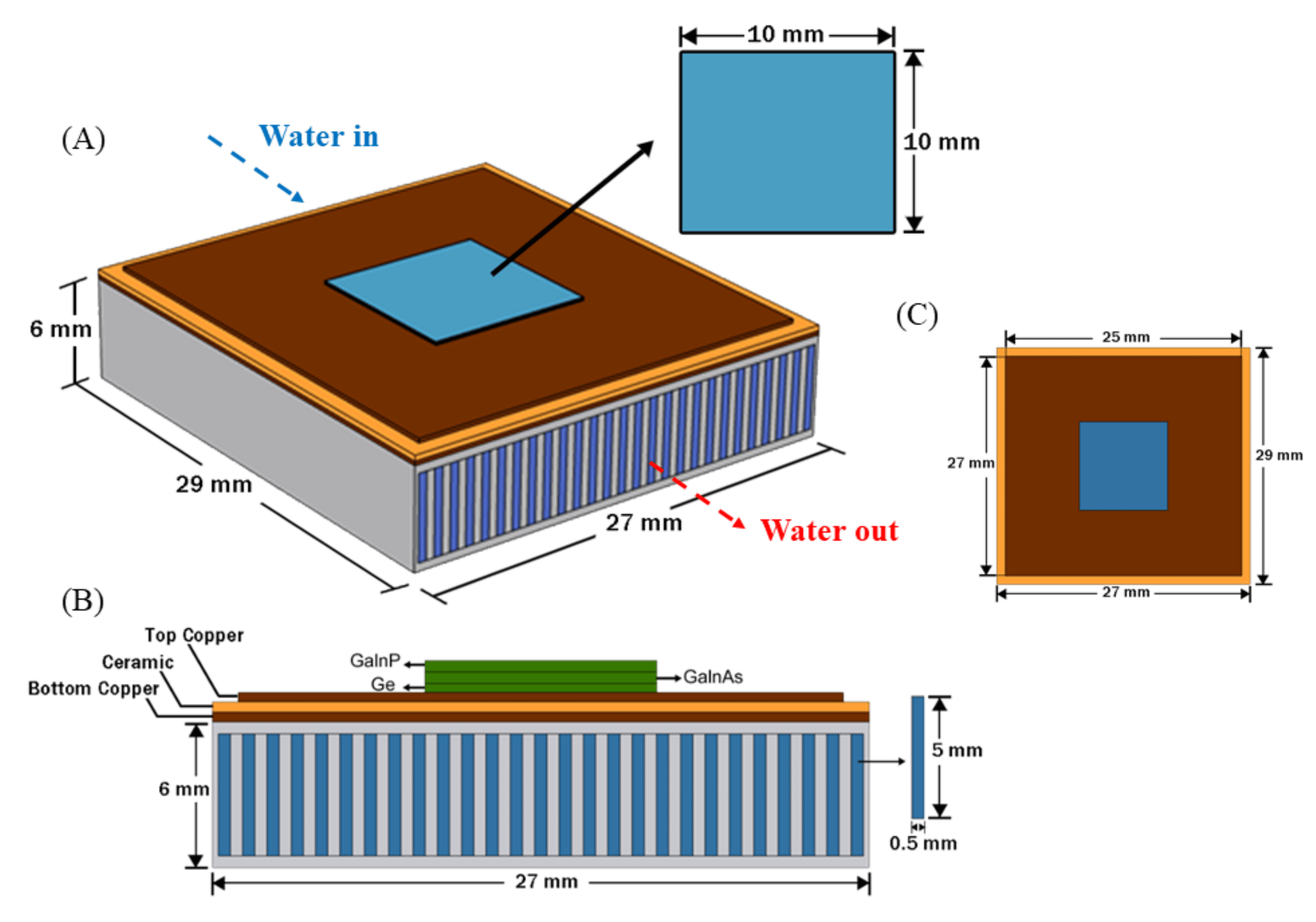

Compact Design for Space Optimization

The compact design of microchannel heat exchangers offers a dual advantage. Not only does it address space constraints in industrial settings, but it also contributes to sustainability by minimizing the physical footprint of thermal management systems. This reduction in size translates to less material usage during construction and installation, aligning with the principles of sustainable resource management.

Versatility and Longevity for Reduced Waste

Microchannel heat exchangers are highly versatile and customizable, allowing for seamless integration into diverse industrial systems. This adaptability ensures that these exchangers can be tailored to specific requirements, prolonging their lifespan and reducing the frequency of replacements. The result is a decrease in the generation of waste materials associated with the disposal of obsolete equipment, contributing to a more sustainable industrial lifecycle.

Applications Across Green Industries

Renewable Energy Systems:

Microchannel heat exchangers find applications in renewable energy systems, such as solar thermal power plants. Their sustainable design contributes to the efficient capture and transfer of thermal energy in green energy production.

Green Manufacturing Practices:

Industries committed to sustainable manufacturing practices benefit from the eco-friendly attributes of microchannel heat exchangers. Customizable designs cater to the specific needs of environmentally conscious production processes.

Efficient Cooling in Eco-Friendly Buildings:

Microchannel heat exchangers play a crucial role in efficient cooling systems for green buildings. The reduced energy consumption and compact design align with the sustainability goals of environmentally conscious construction practices.

Future Trends in Sustainable Thermal Management

As industries continue to prioritize sustainability, the role of microchannel heat exchangers is poised to expand. Ongoing research and development are likely to introduce further innovations, pushing the boundaries of what is achievable in eco-friendly thermal management technology.

Conclusion

Microchannel heat exchangers stand as beacons of sustainability in the industrial equipment landscape. Their reduced refrigerant charge, energy efficiency, compact design, and versatility make them instrumental in promoting eco-friendly industrial practices. As industries worldwide embrace the imperative of sustainable operations, the adoption of microchannel heat exchangers becomes not just a choice but a strategic commitment to environmental responsibility. These eco-friendly innovations are shaping the future of industrial thermal management, contributing to a greener, more sustainable industrial landscape.